menuProduct Center

backtrackYour location:Home → Producs → Drying line

Description

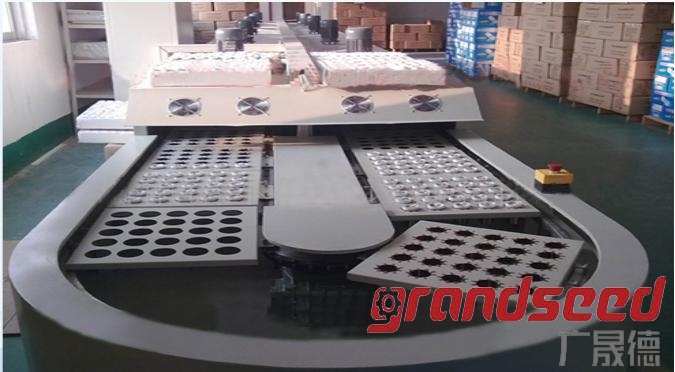

1. Guangshengde 15m U-shaped energy-saving lamp drying line specifications and dimensions:

L15M*W1.35M*H0.80M

2. Introduction to the power part of Guangshengde U-shaped energy-saving lamp drying line

1. The motor adopts Taiwan Kun's gear speed motor with a specific speed of 1:5; WPA80 type 1:40 reducer, 2HP Delta frequency converter, frequency conversion speed regulation, linear speed 0-6M/min adjustable.

2. 1 inch 2 T17 tooth double pitch sprocket with φ60 main shaft and tensioning mechanism as transmission device

3. Introduction to the main part of Guangshengde U-shaped energy-saving lamp drying line

1. Body and frame: The frame is made of 40×40 (mm) rectangular steel pipe welding, the body sealing plate is made of cold plate bending, and the guard plate is made of cold steel plate bending.

2. Conveyor chain: adopts inch double pitch single ear double hole chain produced by Shanghai Chain Factory

3. Drying furnace body: the inner wall is made of 1mm galvanized sheet structure, the outer wall is made of cold-rolled sheet bending, and the insulation layer is made of high-quality aluminum silicate refractory fiber, the thickness is 50mm, and there is a maintenance window per meter.

4. Body color: the surface of the body is made of computer white spray or customized color

4. Introduction to the constant temperature zone of Guangshengde's 15-meter U-shaped energy-saving lamp drying line

1. The inner body of the oven: the whole line of 8 meters high temperature drying room, equipped with light wave heating tube, 8 vertical centrifugal fans, equipped with 8 sets of centrifugal fan blades, effectively circulating the hot air in the furnace. The 1 meter section at the exit is equipped with a cooling fan to facilitate the cooling of the lamp tube

2. Electric control part: It adopts electric heating type, 2 meters 3 1000W/light wave electric heating tubes, temperature automatic constant temperature -120℃, digital RKC temperature control display, relay automatic control, automatic control in 4 sections, each group of heating tubes Discrete air switch control, the temperature of each temperature zone can be set, normal temperature -120℃

5. Introduction to the main control parts of Guangshengde 15m U-shaped energy-saving lamp drying line

1. Electric cabinet: 1.2 mm cold plate is used for bending and rolling into 730×1000×1800mm, 20×40×1.5mm square tube support, arranged in two layers.

2. Control elements: voltage and temperature control instructions adopt digital display type, the whole system adopts PLC and 7-inch touch screen control, and adopts 1 power distribution control cabinet to install. Equipped with an emergency stop switch on the body to facilitate the timely stop when the light is on.

6. Daily output calculation of Guangshengde 15-meter U-shaped energy-saving lamp drying line

Fixture trolley: The fixture frame adopts 20×20 (mm) square tube group welding, and the two sets of panels are formed by cold plate bending and rolling, and the specification is 400×380. A total of 74 sets of small hole mud glue fixture trolleys in the whole line. Each small hole trolley is equipped with 25 sets of 2U or 3U lamp fixtures, which are filled with about 1850 sets of lamps in the whole line. According to a 30-minute operation week, the output is 29,600 sets of lamps in an 8-hour shift; (each set of large 4U 16 sets of hole trolleys).

400-0999-222

400-0999-222