menuProduct Center

backtrackYour location:Home → Producs → Assembly line

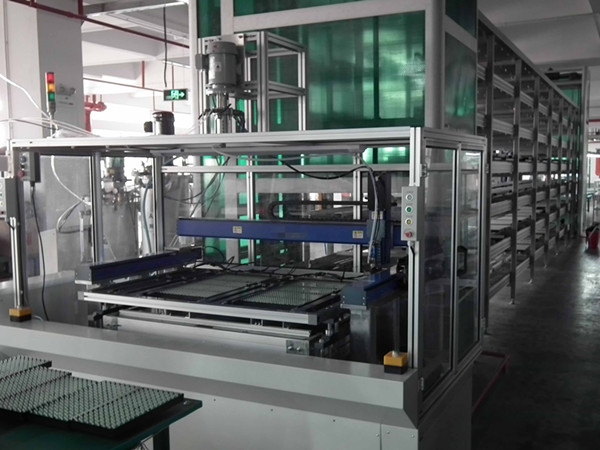

Description

1. Features of Guangshengde LCD display automatic assembly line

1. Fully automatic transportation power system, high efficiency, energy saving, safety, environmental protection, safety, convenience, labor saving, and reasonable design of the whole machine.

2. Each station adopts high-quality blocker and foot switch to independently control, smoothly transition to the next station.

3. The tooling transportation adopts Mitsubishi PLC control, and uses high-performance wear-resistant double-speed chain transportation, which is energy-saving and convenient, and has stable performance.

4. The tooling board adopts a double-layer ring-shaped rotating free transition device, which effectively saves man-hours and improves production efficiency.

2. General configuration of Guangshengde LCD display automatic assembly line

1. Drive system

a, Taiwan Yongkun 3HP horizontal motor 1:100 tooth box;

b. Tooling board speed: 10m/min;

c. The transportation of tooling board adopts RF2060, 3 times speed chain.

2. Lower fuselage line structure

a. The bracket adopts a 50mm*50mm*2.0mm square pass, and the height of the working surface: 740±20;

b. Both sides of the wire body are assembled from super-strength 100*118mm triple-speed aluminum profiles;

c. The lighting adopts T5 18W single LED tube with cover, and the lamp holder material adopts 20*40 iron flat tube. Single-side three-stage control;

d. Each station of the assembly power system is equipped with a long strip of socket, 1.2 meters per set;

e. Three rows of collector rails, with a conductive wheel installed every 200mm;

f. Assemble the quick connector air source triple piece 40SM with 20PH quick connector;

g. The craft Kanban adopts aluminum craft card holder with A4 acrylic board;

h. The wind batch chute adopts 28*35 aluminum material.

3. The upper layer of the aging fuselage line body structured fuselage line structure

a. The bracket adopts 50mm*50mm*2..0mm square pass;

b. Both sides of the wire body are assembled from super-strength 100*118mm triple-speed aluminum profiles;

c. The wire duct is made by bending a cold plate with a thickness of 1.5mm;

d. Install a conductive wheel every 200mm in the three rows of the collector rail;

e. Install a conductive groove in the middle.

4. Detection line

a. The line body adopts 50*50 square pass to make the work surface H750±20mm;

b. Both sides of the wire body are assembled from super-strength 100*118mm triple-speed aluminum profiles;

c. The wire duct is made by bending a 1.5mm cold plate;

d. Three rows of collector rails, one conductive wheel every 200mm.

5. Packaging line

a, Taiwan Yongkun 1HP motor 1: 60 tooth box;

b. Speed; 0-6m/min, 1HP Aideli frequency converter speed regulation;

c. The line body is made of 40*40 square pass, and the height of the worktable is 750+/-20mm;

d. Pull through on both sides of the wire body is made of 40*60mm aluminum profile;

e. Green Holland produced 2mm*1000 PVC anti-static transportation belt, which adopts circular connection, galvanized sheet to support the belt, and ¢25*1000 galvanized drum is installed between the pallets.

6. Repair the car

a. W956*L1300,*H780, 1" bull's eyes are uniformly distributed at 150 intervals, and the tripod is made of 40*40 iron square pass;

b. Aluminum frame, with 2" universal wheels and two brake wheels installed.

7. Hanger: L4000mm, 1 "galvanized pipe, 40*75 flat cross arm, adjusted with M16 screws.

8. Protective fence: 30*30 iron square through welding H1200mm yellow paint.

9. Maintenance channel: 30*30 iron square pass welding is used, and 2mm non-slip iron plate is covered with computer white paint.

10. Electric box: 1. Mitsubishi PLC control; 2. Mitsubishi air switch; 3. OMRON relay.

11. Tooling board

a. Size L 750mm * W 900mm * T 20mm;

b. The tooling board adopts 25mm plywood, 2mm anti-static rubber on the surface, T-shaped edging;

c. Install two two-hole three-hole multi-function sockets and a two-position DIP switch, the back side is pasted with a fireproof board, and three conductive copper bars.

12. Blocker: DY-1 high-quality blocker is controlled by a foot switch.

13. Horizontal blocker: high-quality horizontal blocker with foot switch control.

14. Parallel transplanting trolley

a. 400W reversible brake motor is connected with a pressure box and is driven by a synchronous belt, and is controlled by a frequency converter;

b. Stroke L850 double-row anti-skid belt, gear reduction motor 60W, three collector rails.

15. Lifting and transferring trolley for tooling plate

a, Toho 60W reduction motor drive synchronous belt conveyor

b. Lifting adopts 60W motor and tooth box with solenoid valve for lifting

c. The control adopts OMRON travel switch.

16. Hoist

a, W1010, L1910, stroke H750-H2720 double row anti-skid belt, 60W gear reduction motor

b. The lifting adopts a 6-point chain, and is controlled by a Taiwan motor 0.4KW reversible brake motor tooth box inverter;

c. Externally sealed plexiglass and decorative aluminum.

400-0999-222

400-0999-222