menuProduct Center

backtrackYour location:Home → Producs → Automated production line

Description

1. Overview of the full-automatic assembly line for vertical LED bulbs

1 The output of the whole line is 1200-1500PCS/H

2The entire line has 3-4 operators (equivalent to 16 ordinary production lines with a capacity of 13000PCS in 8 hours)

3The pass rate of the whole line is greater than or equal to 98% (except for poor raw materials)

4 The whole line has an automatic port, which can be upgraded to automatically connect to the aging line.

5The cost of the whole line is economical and suitable, and it takes up a small space

6 For small batch products, some automation functions can be selectively used

7 The equipment can be upgraded to remote network service, and can handle training and maintenance work (extra cost)

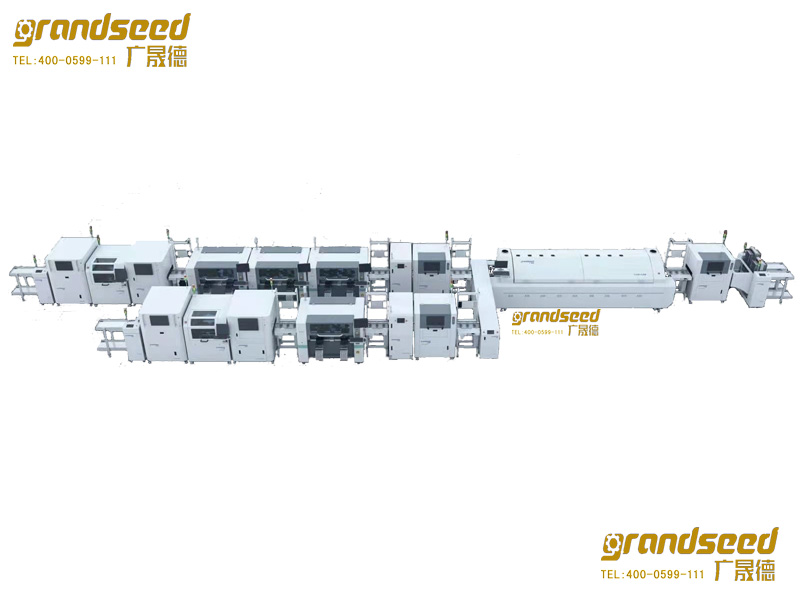

Vertical LED bulb automatic assembly line

2. Upright LED bulb fully automatic assembly production line configuration

1. Adopt 4 four-axis robots (400 stroke)

2. The power supply-light-emitting board assembly machine requires 1 operator, aluminum substrate (light-emitting board), and can take into account the arrangement and feeding of other raw materials.

3. Realize automatic synchronization control through feeding operation. There are two ways to feed the bulb of the lamp holder-bubble shell assembly machine. The material is loaded on the vibrating plate/or directly placed in the direct vibration manually, depending on your company's blister material and process.

4. The machine operating speed is 1200-1500pcs/hour, and the pass rate is greater than or equal to 98%;

5. Control system: OMRON-PLC other components OMRON or its quality equivalent brand;

6. The pneumatic valve adopts a safety voltage of 24V, and the main motor is 380V, 50HZ;

7. Pipeline gas requirements: high pressure wind 0.5~0.8MPa;

3. The requirements for raw materials in each process of the upright LED bulb fully automatic assembly production line

1. The buyer must provide materials in strict accordance with the material requirements provided by the supplier. If the supplied raw material products do not meet the relevant process parameters of the supplier’s technical contract, the buyer must improve the raw materials until they meet the technical raw materials. Generally, the two major factors that lead to the low pass rate of defective equipment (lamp cap and wire) ), the buyer only needs to make minor adjustments to improve these two materials, which will not lead to an increase in the cost of raw materials. In order to meet the needs of automated assembly, the supplier has the following requirements for the process documents of the buyer's materials:

2. According to the LED bulb size chart provided by your company, since there is no actual product at present, there are two ways to load plastic-coated aluminum: vibrating plate feeding or artificially arranging it into the feeding chain. If plastic-coated aluminum uses the vibrating plate to vibrate the surface If there is no grinding and blackening, give priority to using the vibrating plate for feeding.

3. The lamp holder material requires no cracks when it meets the requirements of the indenter depth (torque);

4. After the power supply is assembled, the exposed length of the lead (single strand of bare wire) ~40mm is shown in Figure 1;

5. When the assembly torsion of the lamp holder bulb meets the technological requirements, the chamfer of the lamp holder entrance should be as large as possible;

6. The aluminum nail material is required to be consistent in size, and the material needs to be replaced if the length does not get stuck.

7. The chamfer inside the lead hole of the aluminum lamp holder meets the technical requirements (see attached picture 2);

LED bulb lamp automatic production line working video

400-0999-222

400-0999-222