menuProduct Center

backtrackYour location:Home → Producs → Automated production line

Description

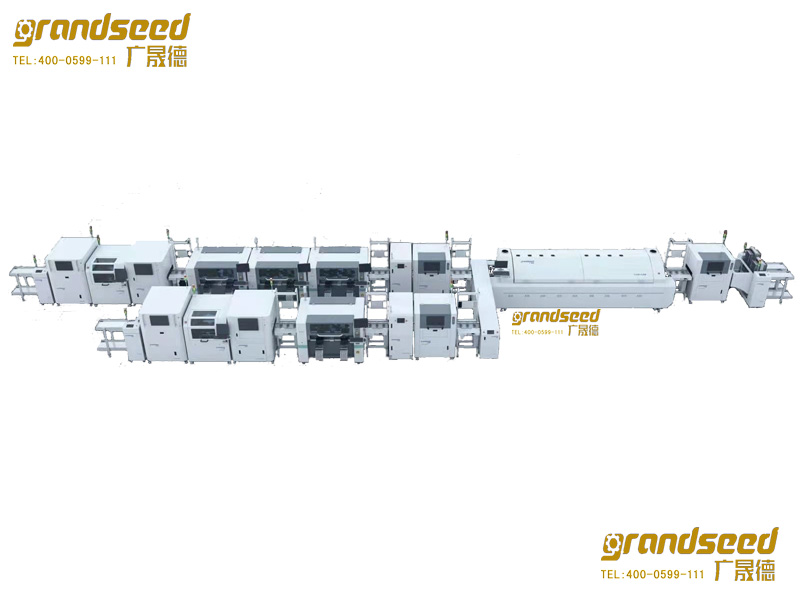

一、The main function and purpose of the automatic assembly line of LED fluorescent tube

Through the mechanical automation of the LED strip light assembly line, automatic loading and unloading of products, automatic insertion of lamp beads, automatic automatic welding line assembly and inspection are realized, so as to achieve the purpose of saving labor, controlling quality, high efficiency and high yield.

2. Overview of the functions of the automatic assembly line for LED fluorescent tubes

1. The main line adopts a 3.0 times speed chain belt carrier plate fixture flow conveying method

2. The tooling board adopts 1 out 3 separate positioning method

3. Lifting lamp tube silo automatically arranges, grabs and feeds materials

4. The light bar manual dividing machine is divided into the card slot and automatically guided and pushed into the lamp tube

5. Manual feeding of single-line lamp holders (soft wires), automatic stripping, grabbing and placing into the tooling board

6.

a. Manually load the card line on the power supply board with the line, and automatically move the cable and strip the line

b. Line lamp holders are automatically loaded and arranged (visual positioning) and automatically marked (laser)

c. The power board and the lamp holder are assembled and riveted first, and then automatically grabbed and put into the tooling board

7. Automatic soldering (three-axis soldering machine)

8. Automatically install the lamp holder (six-axis robot)

9. Automatic power test

10. Automatic picking and sorting of NG products

11. The finished product is automatically captured and output

12. The hoist at both ends of the line body automatically returns to the plate cycle

3. Working video of Guangshengde LED fluorescent tube automatic assembly production line

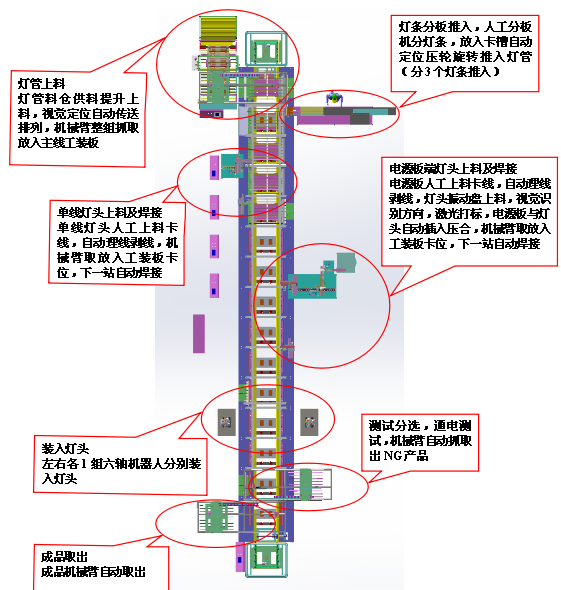

三、The overall engineering process flow chart of the automatic assembly line of LED fluorescent tubes

LED灯条全自动组装线工艺流程图

400-0999-222

400-0999-222